What Is GWO Basic Safety Training?

September 5, 2025

GWO Training Prep: What to Expect & How to Succeed

November 6, 2025The silhouette of a wind turbine against a vast sky is an impressive sight, a symbol of clean energy powering our future. But maintaining these colossal structures, especially their massive blades, is a monumental task. For years, the only way to thoroughly inspect a blade was for a highly skilled technician to rappel down, often in challenging conditions.

Enter the drone: agile, precise, and now, an indispensable co-pilot for wind turbine blade technicians. What once involved harnesses, ropes, and hours suspended hundreds of feet in the air, is now being revolutionized by automated drone technology. Let’s dive into how these flying marvels are changing the game, making the wind industry safer, more efficient, and more technologically advanced.

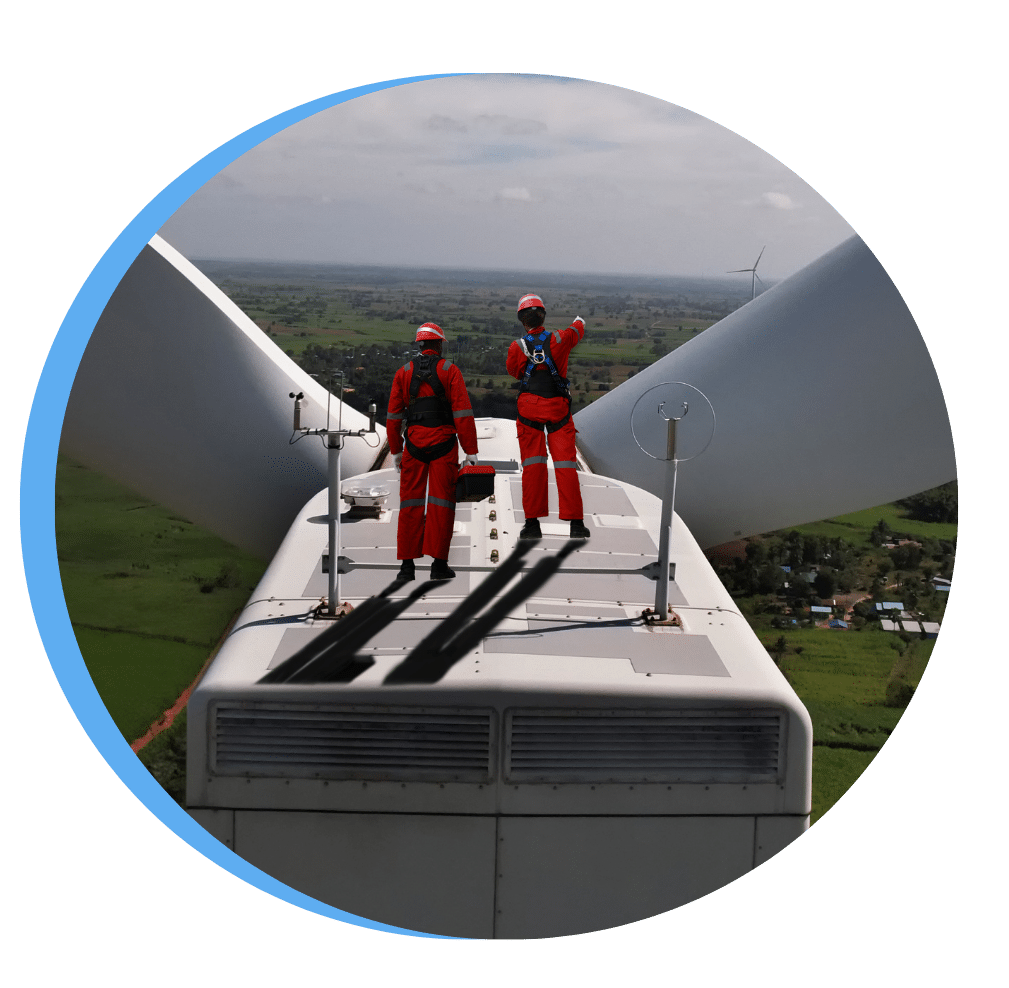

The Old Way: A Heroic, Yet Risky Endeavor

Imagine being a blade technician. You’re at the top of a turbine, perhaps 300 feet or more off the ground, exposed to the elements. You’re meticulously inspecting every inch of a blade that can be over 200 feet long. You’re looking for hairline cracks, erosion, lightning strike damage, or manufacturing defects that could compromise the turbine’s efficiency or even its structural integrity.

This work requires incredible skill, bravery, and physical endurance. It’s also time-consuming and inherently risky. Weather conditions can change in an instant, and every minute spent suspended in the air carries a degree of hazard. While this traditional method remains vital for certain in-depth repairs, the initial and routine inspections are where drones truly shine.

The New Way: Precision, Speed, and Safety from Above

Modern wind turbine inspection drones aren’t just consumer gadgets with cameras attached. These are sophisticated pieces of engineering, often equipped with high-resolution optical cameras, thermal imaging, LiDAR (Light Detection and Ranging), and even ultrasonic sensors. They are specifically programmed for autonomous blade inspection missions. Here’s a breakdown of the process:

- Mission Planning: Before a drone even takes flight, technicians or specialized drone operators meticulously plan the inspection route. They input the turbine’s specifications, including blade length, the desired distance for imaging, and the number of passes required. The drone’s software then calculates an optimal, repeatable flight path.

- Autonomous Flight: Once programmed, the drone takes off and executes its mission with remarkable precision. It flies around each blade, capturing thousands of high-resolution images from various angles and distances. Many systems can complete a full 3-blade inspection in less than 30 minutes, a fraction of the time it would take a human crew.

- Data Collection & Analysis: This is where the magic truly happens. The drone collects a massive amount of visual and sensor data. This data is then fed into specialized AI-powered software. This artificial intelligence can automatically identify, categorize, and even measure anomalies on the blade surface. It can detect a tiny crack, a leading-edge erosion, or even a subtle discoloration that might indicate an internal issue.

The Data Advantage of Drone Inspections: More Than Just Pictures

The information gathered by drones goes far beyond simple photographs.

- High-Resolution Imagery: Drones capture images with such clarity that even microscopic defects can be spotted. This allows for early detection of problems before they escalate into costly repairs.

- Thermal Imaging: Infrared cameras can detect temperature differentials, revealing internal structural issues or water ingress that might not be visible to the naked eye.

- 3D Modeling: Advanced drones can create detailed 3D models of the blades, allowing technicians to precisely locate defects and track their progression over time. This is invaluable for predictive maintenance.

- Historical Data Tracking: Over multiple inspections, the software builds a comprehensive digital history of each blade. This trend analysis helps operators understand degradation patterns and schedule maintenance proactively.

How Drones Elevate the Wind Turbine Blade Technician’s Role

While drones take on the repetitive and dangerous task of initial inspection, they certainly don’t replace the human element. Instead, they transform the technician’s job, making it more strategic, analytical, and safer.

- Enhanced Safety: This is perhaps the most significant benefit. Fewer hours spent at height means dramatically reduced risks of falls or exposure to severe weather. Technicians can analyze data comfortably and safely from the ground or an office.

- Increased Efficiency & Productivity: Drones can inspect multiple turbines in a single day, dramatically increasing the number of blades that can be monitored. This frees up human technicians to focus on the more complex, hands-on repair tasks that only they can perform.

- Smarter Decision-Making: With highly accurate and consistent data, technicians can make informed decisions about maintenance priorities. They know exactly where a defect is, how severe it is, and whether immediate action or continued monitoring is required.

- Specialized Skill Development: The rise of drone technology creates new opportunities for technicians to develop expertise in drone operation, data analysis, and software interpretation. These are valuable, high-tech skills that future-proof their careers.

- Proactive Maintenance: Early detection of small issues means fewer catastrophic failures. Technicians can schedule preventative repairs, minimizing downtime and maximizing energy production.

The Future is Bright (and Automated)

The integration of drones into wind turbine maintenance is a testament to the wind industry’s commitment to innovation, safety, and efficiency. For aspiring wind turbine technicians, understanding and embracing these technologies is no longer optional; it’s a critical component of a successful and rewarding career.

At Windtrade Academy, we believe in equipping our students with the most current knowledge and skills. As the wind industry continues to evolve, so too will our training, ensuring that our graduates are not just ready for today’s challenges, but for tomorrow’s innovations – with a powerful new co-pilot by their side.

Ready to learn more about a career in the dynamic world of wind energy? Explore our GWO-certified training programs and get ready to climb to new heights – even if some inspections are now done by drone!