Amazon signs PPA for Oregon wind project undergoing repowering effort

February 12, 2024

Turbine bearing supplier Malloy completes warehouse expansion

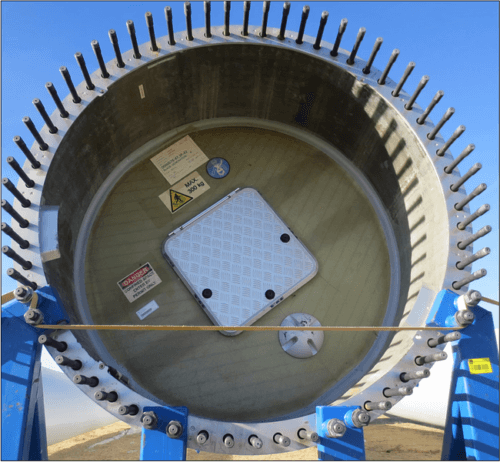

February 20, 2024ONYX Insight has launched a blade root connection monitoring system following extensive field testing.

The system is scalable across entire fleets, with a finely tuned selection of sensors, sensor placement and data analytics, reducing manual visual inspection requirements within the turbine hub and blades. This in turn reduces the need for turbine climbing and improves safety. During two years of field testing, the technology has been proven on over 3,000 blades across 1,000 turbines, demonstrating highly effective and accurate fault detection.

Blade root connection failures are a growing issue across the wind industry and are not limited to any one turbine type or blade manufacturer. Some design concepts and blade models have experienced particularly high failure rates in the field and are a natural target for continuous online monitoring. If not addressed early, blade root connection failure can lead to blade loss or, in extreme cases, full turbine collapse. This can seriously impact asset profitability, with a single blade replacement costing approximately $300,000 to $500,000.

Dr. John Coultate, Vice President Advanced Sensing at ONYX Insight, said: “We recognize the increasing industry challenge in tackling blade root connection failures and our latest technology enables owners and operators to quantify the risk of unplanned blade maintenance accurately. By providing clarity and visibility, operators can confidently run turbines knowing they will always be one step ahead of potential issues.

“ONYX’s data-driven approach allows operators to focus visual inspections on validating and managing known issues instead of investing time and expense into manual checks across an entire fleet. This predictive approach to maintenance provides actionable data insights which significantly reduce asset downtime while increasing turbine productivity.”

The blade root connection monitoring system expands ONYX Insight’s large range of sensing devices available on the wind market, including ecoCMS, ecoCMS Flex, ecoPITCH and fleetMONITOR, which provide predictive maintenance across components, including drivetrains, pitch bearings, towers and foundations.

News item from ONYX

Filed Under: News